Flax is ecological by essence.

Today with the worldwide great concerns about the future of our planet, we have a wonderful opportunity to promote flax, the natural fiber we have been weaving for the past 150 years.

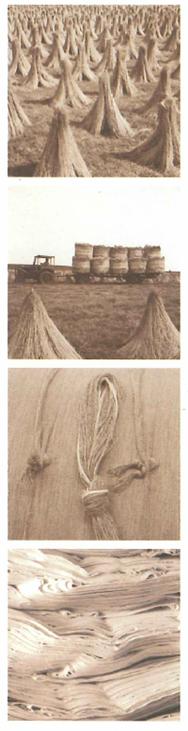

GROWING OF THE FLAX PLANT

Flax has grown for thousands of years, and always with great respect for the environment.

Flax is a plant that grows naturally, with very few chemicals used (much less than other crops).

For growing flax no irrigation is needed.

The flax plant is gentle on the land and flax is easy to incorporate into modern crop rotation cycles.

The processing of flax needs very little energy and does not harm nature.

Water retting process has been replaced by the environmentally friendly dew-retting on the field.

FLAX, BY NATURE A “GREEN” PRODUCT

Flax has some inherent ecological characteristics as all parts of the plant are used (there is no waste) and are 100% biodegradable or recyclable.

Flax seed is beneficial in human and animal nutrition because of its very high content of alpha omega-3 fatty acid. Flax seeds can be used as the base for a fine flour used in medical compresses.

Linseed oil, squeezed out of flax seeds, is also used as a component in paints, cosmetics, soil coverings, etc.

Flax fibers are also being used in heat insulation, packaging, etc.

The remaining residual products are used in fiber boards, bank notes, etc.

The inherent strength of linen yarn reduces the need for starching during spinning and weaving.

Linen fabrics can be recycled into paper and insulation materials for the car industry.

FROM FIBER TO FABRIC : spinning & weaving

The industrial processes of spinning and weaving have very little to no impact on the environment. Libeco-Lagae is constantly investing in new equipment and production methods, reducing the need for energy and water and eliminating or recycling most of the waste. As a source of energy we use natural gas and do not pollute the air. Constant improvements on the machinery will allow us to limit the use of energy. We are constantly continuing our research in order to improve our production methods and limit even more our impact on the environment.

FINISHING LINEN FABRIC : bleaching & dyeing

Bleaching and dyeing is the most delicate part of the linen production chain, from the aspect of ecology. Our partner Verlimas is the most advanced factory in this field. They have heavily invested to comply to all strict E.E.C.- rules.

Their process water is not pumped from deep water reserves (which are becoming scarce) but is pumped from the river Lys and is filtered before use. All waste water is processed by a state of the art biological water-recycling plant on the premises and is then released back into the river. The quality of the released water is constantly monitored and is respecting all norms.

The use of chemicals is under very strict control here and all their chemicals and dyes comply with the strict European REACH-regulations. For bleaching dangerous chloride has been replaced by a peroxide bleach. For dyeing harmful dyestuffs are being replaced with new, non-toxic formulae. We are also studying the possibility of using all natural dyes.

ECO LINEN FROM LIBECO-LAGAE

Another great advantage of linen is its typical “natural” color obtained by the interaction of the plant with the sun, the rain and the earth. Approximately 40 % of our sales come from these natural, undyed fabrics. All of our natural fabrics can wear our ECO LINEN label : tests have shown that no chemical residues are found in the final product.